|

|

|

|

Product quality is an important part of purchasing

decision today and in the future, which means that we shall aim to manufacture

to the highest standards and maintain our production facilities and process

systems at the same high level.

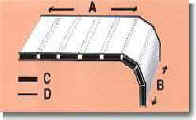

Lamiflex is

a flexible composite material with a core of board (C)

with different types of protective paper on each side (D).

These papers can range from the ordinary craft type to polythene coated, and /

or anticorrosion paper or special fiberglass reinforced papers. The core

material has a thickness of 3, 4 and 8 mm with a strip length (B)

ranging from 150 mm up to 6200 mm.

A – Running length

B – Strip length

C – Base material

D

– Inner and outer layer

These components are hardboard, which is produced of

pure wooden fibers, paper and hotmelt. The inner papers are of three types: R

(craft paper with an anti-corrosion protection), T (polythene coated craft

paper) and S (craft paper). The outer paper is usually a UV-stabilized, water

repellant grade.

As result of this flexible material structure, Lamiflex

is easy to handle adapts to the form of all identically shaped industrial

products and is reusable also for other packaging purposes by simply cutting to

pack size.

Lamiflex comes fan folded on pallets in a

continuous width cut to required length. Working with Lamiflex

is easy, fast and cost effective when compared to traditional wooden battens.

Lamiflex can be overprinted to enhance product

awareness and customer appeal.

Lamiflex

has been tested by a number of packaging institutes for land, sea and air

transportation always with the same good results.

Copyright © 2003

Projects

One. All rights reserved.